What are differences between BMS, PMS, EMS?

In a co-located or hybrid power plant, various systems can be used to monitor and control energy generation and distribution. Here are the differences between Battery Management System (BMS), Power Management System (PMS) and Energy Management System (EMS):

Battery Management System (BMS):

The BMS is specifically responsible for monitoring and managing batteries or energy storage systems. It monitors the condition of the batteries, including the state of charge, temperature, and other relevant parameters to ensure their safety and that no operating modes are executed which are not permitted. The BMS provides protection features to protect the batteries from overcharging, deep-discharging and other harmful conditions.

Typically, every battery manufacturer has his own BMS which is provided together with the batteries. If the battery consists of several battery racks or containers, each of them has usually a BMS which overtakes all the tasks, functions, and the protection for the respective rack/container. A Master-BMS is than monitoring, balancing, and protecting the whole battery system.

Power Management System (PMS):

The PMS is responsible for monitoring and controlling the energy generation and distribution throughout the power plant. It also ensures the grid code compliance at the point of common coupling (PCC) and keep the internal grid stable. It optimizes power generation and distribution to ensure that the power needed is provided and the systems operate efficiently and safely. This includes the coordination of different energy sources and energy storage systems. To do so the PMS needs input values from the underlying sub-systems i.e., the BMS. The PMS can also provide protection functions to protect the power plant from overload or other grid disturbances.

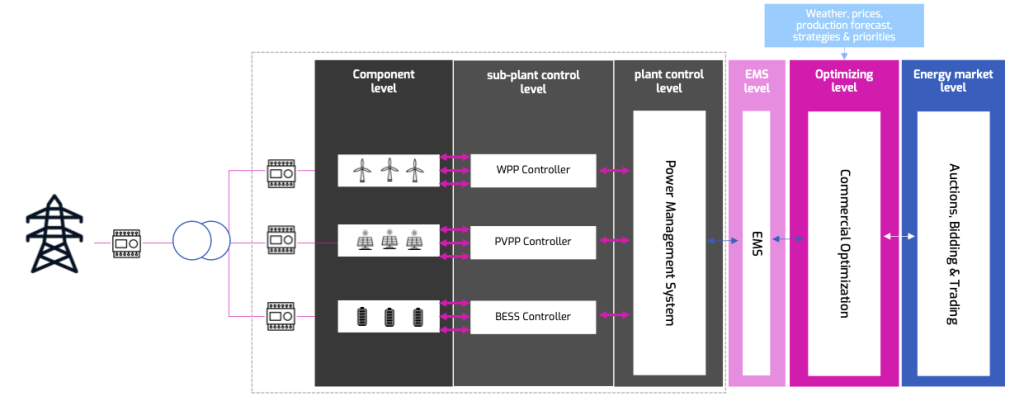

Based on the complexity of the plant and the plant layout there could be several control levels like asset control level, sub-plant control level and the overall Power Management System. It follows the same principle as the BMS. As an example, if there are several asset parts like pv generator, wind turbines, battery system etc. each of the components – e.g., every wind turbine – can have its own controller. On the next level there could be a sub-plant controller which is than controlling and balancing e.g., the whole wind farm. The power management could then be another layer which is also considering other parts of the whole plant like the battery system and the whole pv generator. The PMS then adapts and calculates the power setpoint for each-sub-plant to execute the energy setpoint at the PCC which it received for example from an EMS, through the SCADA system or the grid operator.

Energy Management System (EMS):

The EMS has multiple responsibilities:

- Monitoring and control: An EMS continuously monitors the various components of a renewable power plant, including wind turbines, pv system, battery storage systems, and other energy sources. It collects data in real-time to ensure that all parts of the system are working as expected and that the current operation schedule can be executed properly. An EMS can often be monitored and controlled remotely, making the maintenance and operation of a renewable power plant more efficient.

- Forecasting & Optimizing: The EMS uses weather forecasts and other data like prices, costs to predict the expected energy production and load. It also considers given constraints, like market rules, physical limits of the asset or warranty and contractual conditions. This allows it to optimize the operation of the power plant in advance and in a way that the produced energy is utilized the most profitable.

- Execution: The EMS can be seen as an additional layer which adds intelligence to the plant. It is responsible to calculate the most economic profitable dispatch plan for the next time under the given circumstances and according to the optimization target and use case(s). It ensures that all framework conditions are considered and that the whole system works efficiently to maximize the overall performance and can fulfill the underlying use case(s) of the plant.

Overall, an energy management system helps to increase the reliability and efficiency of renewable power plants & facilitate the integration of renewable energy into the power grid.

To sum up: In a co-located or hybrid power plant, these systems usually work together to ensure that the batteries operate properly, that energy production is optimized, and that the power distribution meets demand and efficiency requirements. To simplify it we can describe it in a way that the BMS acts on the low level, PMS on the mid-level and EMS at Top-Level to balance all involved subsystems which is shown in the graphic below.

We can see them as different layers in the control part of the asset and with every level one can add more and more intelligence to the plant. Why?

While the BMS focuses on the batteries, the PMS focuses on the performance of the entire power plant, and the EMS optimizes the overall energy flow and efficiency under the premise of achieving the economically optimized result by considering forecasting, prices, and costs.